The Basic Principles Of 24hr Media

The Basic Principles Of 24hr Media

Blog Article

Fascination About 24hr Media

Table of ContentsThe Best Guide To 24hr Media8 Easy Facts About 24hr Media ExplainedRumored Buzz on 24hr MediaRumored Buzz on 24hr MediaThe Only Guide for 24hr Media

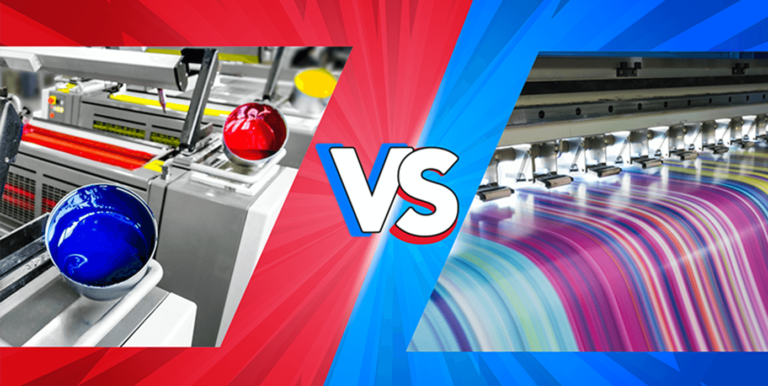

Developments in print modern technology are altering the interactions playing area when it involves quality, cost and innovative abilities. Countered printing and electronic printing are the significant processes through which print tasks are taken on both utilizing four-color printing methods. Each alternative has its advantages, using different strategies to satisfy the requirements of varied production jobs.

Usually, this has actually been one of the most regular technique for exactly keeping color suits, making it optimal for print runs that just require fixed printing such as pre-printed forms, pamphlets, leaflets, service cards, and mass postcard mailings. Nevertheless, because of the static nature of litho printing, it is not excellent for variable print items that will certainly be sent by mail to specific receivers such as declarations, letters, and individualized postcards.

The Definitive Guide to 24hr Media

The newest improvements in print modern technology are helping to bring many of balanced out's advantages right into the electronic printing globe genuinely transforming the face of modern-day printing! There are some key differences between Offset Printing and Digital Printing.

Today's digital print equipment is among the most innovative on the market. Right here are a few of the greatest benefits of making use of electronic printing: control the electronic print room, with full-color printing finished in one procedure and flawlessly published straight from a print data. Without a prolonged set up process, the calibration time of a particular task is shortened, contributing to quicker print time and overall distribution.

The inkjet printing procedure has actually assisted to transform the sector in addition to the high quality and speed of the result. The most up to date inkjet modern technology can publish on standard balanced out stocks with dull, silk, and shiny surfaces. Top notch digital print coupled with software-managed shade monitoring methods adds optimum worth to print items and makes production processes extra trustworthy than balanced out.

The Best Strategy To Use For 24hr Media

(https://www.magcloud.com/user/za24media)

Environment-friendly and naturally degradable inks and toners are additionally offered for more lasting printing. Digital print additionally eliminates the need to clean plates or blankets with dangerous chemicals at the end of the printing process.

Variable data helps organizations reach their specific clients and audience with uniquely-created and customized material. As technology boosts, the high quality of digital printing has actually ended up being second-to-none, with better information, color suit capabilities and total precision. Without the demand to wash plates or use excess ink, electronic printing is likewise much less inefficient and generally more eco friendly.

Traditional printing techniques, such as offset lithography ("countered") and flexography ("flexo"), involve numerous make-ready steps to move an original picture to a substratum. These techniques call for the production of a collection of plates mounted on a cylinder to move ink that forms the wanted image when integrated on paperboard and various other packaging products. Custom Printed Packaging.

Rumored Buzz on 24hr Media

Digital printing, with fewer relocating pieces, is a lot more active than balanced out in this regard.

Lowered set-up time conserves money on the front end. And given that these are not substantial mass orders, smaller businesses can manage to print without having to fulfill the greater and much more pricey print limits of traditional printing.

Make sure you team up with a printing and packaging companion who has the best certifications. While eleventh-hour printing and modification are a significant benefit, electronic may not always be the very best approach for you. Balance out printing has the advantage of cost-effectiveness with huge print runs, especially those with innovative ornamental results and specialty coatings.

Facts About 24hr Media Uncovered

The favorable plate, with its smooth surface, brings in oil-based inks and pushes back water. In contrast, the adverse plate, with its rough appearance, absorbs water and drives away oil. Rubber rollers are then made use of to transfer the photo from the plate to the corrugated surface.

Corrugated paper can often show to be a tough surface to print on, yet Litho prints to a separate surface area and is after that laminated to it, making it simple to publish premium photos. It can be incredibly regular, even for futures. Actually, the much more you publish, the cheaper the expenses come to be for Litho.

If you have adequate time and budget, and a big volume of a solitary layout, after that there shouldn't be a problem. What Litho doesn't provide you is specifically what Digital does, personalization. A lot more on that later on. Pricey set up Longer turnaround No Variable Data Printing Smaller color range, shades can be much less bright Digital printing is the procedure of printing digital images directly onto the corrugated substrate utilizing a single-pass, direct-to-corrugate method - Custom Boxes.

Report this page